|

[ New Concrete Surface] - Surface Condition Tensile Strength : Over 210kg/cm2 Slump: Approx. 10 to 15 cm Neutralize Acid & Pressure Washing if high pH [ Existing Concrete Surface] - Indoor Concrete Finish Shot Blast if required Pressure washing with water - Outdoor Concrete Finsih Scrub Surface with water Pressure washing with water |

|

|

Use mortar mixer and prepare the mixture of Dynatex Primer and Dynatex Body Coat. | |

|

Fog the surface with Water | |

|

Apply the Dynatex Primer Mixture Coat with Metal Squeegee | |

|

Dump the Dynatex Body Mixture Coat over the wet Dynatex Primer Mixture Coat | |

|

Spread Dynatex Body Coat with 9.5 mm thickness Guage Rake | |

|

Smooth out the spreaded Dynatex Body Coat. Recommeded to use "Fresno" to have easy & fast application. | |

|

After lightly spraying the surface, carefully trowel it smooth with the funny trowel by working it from side to side like a stand up hand trowel. | |

|

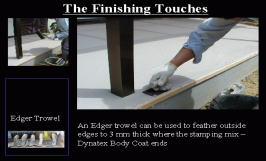

An Edger trowel can be used to feather outside edges to 3 mm thick where the stamping mix Dynatex Body Coat ends | |

|

Spray the Dynatex Releaser which can be releasing agent for the stamp and second color for antiquing finish. | |

|

The Skin Texture are used to apply texture next to walls and other areas the regular stamps or floppy stamps cannot reach. They are also used to touch-up any areas where the regular stamps did not leave enough texture due to the surface being too hard as being dry. | |

|

Carefully stand on the first texture stamp to see if the material is firm enough to support your weight without squishing up around the sides of the stamp. If it supports your weight and doesn't feel too soft, you can begin the stamping process. | |

|

Placing More Stamps Next To The First One

& Moving The Stamps. All the stamps should fit tightly together like a puzzle. It is important to always keep the tight up against each other or the pattern will be hard to keep line up. |

|

|

Use The Pounder Or Your Feet To Imprint The Texture if the stamping material seems hard. | |

|

Using touch-up tools for the grout flues

when it is wet. While stamping, one person

needs to be checking the grout lines after

lifting each stamp to see if any touch-up

will be needed. Also next to walls and vertical surfaces it will be necessary to create your own grout lines where the stamps could not reach next to the edge. |

|

|

While stamping, one person needs to be checking

the grout lines after lifting each

stamp

to see if any touch-up will be needed.

Also next to walls and vertical surfaces it will be necessary to create your own grout lines where the stamps could not reach next to the edge. |

|

|

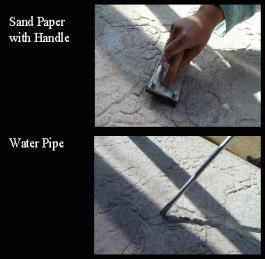

Using Touch-up Tools For The Grout flues after it is dry | |

|

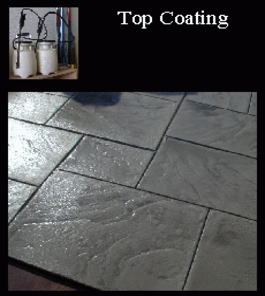

Dynatop U is a non-breathable moisture cure solvent base urethane that will darken the stamped concrete application and will also provide a high gloss appearance. It has durable and chemical resistant. It is recommended for high traffic areas or some indoor jobs where high gloss, chemical resistance and increased durability are desired. It is applied by airless sprayer or using a 1/2" roller and will cover approximately 0.1 to 0.15 ltr/m2. |